TECHNOLOGY

FITTING TECHNOLOGY

Let me introduce the unique technology of Dury Chemical

DTS

(Direct Taper System)

FEATURE #01

1st generation Adhesive bonding method

It is a method of connecting pipes and fittings chemically by using adhesive. It requires high level of experience and skill of worker and needs long construction time due to considerable bonding time.

-

① Cutting

-

② Chamfering

-

③ Adhesive application (fittings)

-

④ Adhesive application (pipes)

-

⑤ Assembling → Adhesive curing

-

⑥ Completion

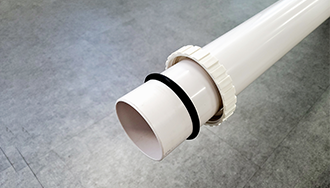

URF

(Union Rubber-ring Fitting)

FEATURE #02

2nd generation Compress tightening

It is a method of coupling a pipe and a fitting by the tightening force after turning and tightening a cap (a rubber ring and a cap in the joint portion of a fitting). It does not require a high level of work skill, but it requires some pre-work (inserting a pipe after separating the rubber ring and the cap) and a special tool to tighten the cap.

-

① Cutting

-

② Separation of a rubber ring and a cap

-

③ Coupling the rubber ring and the cap

-

④ Assembling

-

⑤ Cap tightening and finishing (using dedicated special tools)

BCF

Bolt-action Clamp Fitting

FEATURE #03

3rd generation Clamp tightening

It is a method of coupling a pipe and a connecting fitting by the clamping force after turning and tightening the bolt of a clamp (a rubber ring and a clamp in the joint portion of a fitting). It does not require a high level of work skill. Without pre-work, you can just insert a pipe into a fitting and easily combine the fitting and pipe using an electric drill. For this reason, the work speed is fast and the joint strength after fastening is higher than previous conventional method.

- Quick and easy assembly without separating the cap and the rubber ring

- Flexible assembly without space limitation due to rotational clamp

- Stable and strong fastening due to clamping method

- Quick and easy construction with an electric drill by using the one-point bolt fastening method

- 100% reduction in construction time, compared to URF!

- 300% increase in the combination strength, compared to URF!

-

① Cutting

-

② Assembling

-

③ Clamp tightening (an electric drill) and finishing

Coupling technology

feature

| 1st generation DTS method | 2nd generation URF method | 3rd generation BCF method | |

|---|---|---|---|

| Overview | Chemical bonding between pipes and fittings with adhesive | Compress fitting with the tightening force generated by turning the cap | Tighten pipe and fitting using one-touch clamp technology |

| Material | Hard PVC | PP (pipe fitting, cap) + Rubber (ring) | Hard PVC (pipe, pipe fittings, cap) + Rubber (ring) + Metal (clamp bold) |

| Couple method | Chemical adhesion | Cap tightening | Clamp compression |

| Structure of connecting fittings | Body | Body, cap, ring | Body, clamp, ring, bold, nut |

| Dedicated tools | Dedicated adhesive, bond brush | Special fastening tool | General electric drill |

| Workability | |||

| Construction speed | |||

| Cohesion strength |